How Copper Is Mined And Extracted

Nothing illustrates the beauty and durability of copper more than the Statue of Liberty. Despite exposure to more than 130 years of gale-force sea winds, pounding rains and scorching sun, Lady Liberty’s copper skin has only grown more beautiful and remains largely intact. The Statue's rich, green patina is poof of copper’s ability to withstand the vagaries of time. Chemical analysis shows that only .005 inches of weathering and oxidation have occurred since installation in 1884, further testimony to copper’s longevity.

The Statue of Liberty is just one just one example of copper’s aesthetics and endurance. Copper art objects have graced museums and homes for thousands of years, and the metal is often a fundamental ingredient in decorative products for the home, such as bathtubs, door hardware, railings and trim. Its conductive characteristics make copper an effective electric conductor for household appliances and electronics, and it’s also a preferred material for plumbing and roofing applications. Keep reading to discover the fascinating history of copper with CopperSmith!

So, What’s The Story About Copper?

The history of copper is special because copper is the first metal used by humans in quantity.

By about 6400 B.C. the Turks were melting and casting copper into various decorative objects, which the Egyptians then copied around 4000 B.C.. Most of the copper used by the Turks came from natural surface deposits or from meteorites that had fallen to earth. In the history of copper, the first historical mention of the organized extraction of copper ore occurred in about 3800 B.C. in an Egyptian reference to Sinai Peninsula mining operations.

About 800 years later, after the Romans discovered large deposits of copper ore on the island of Cyprus, the conquerors gave the metal a Latin name—aes cyprium—that eventually shortened to cyprium, changed to cuprum, before its final adoption of the English incarnation, word copper.

Copper was in use as early as 500 B.C. in Peru, and copper metallurgy was in full bloom by the time the Inca Empire fell to the Spanish in the 1500’s.

The first copper mine in the United States began operation in Branby, Connecticut.

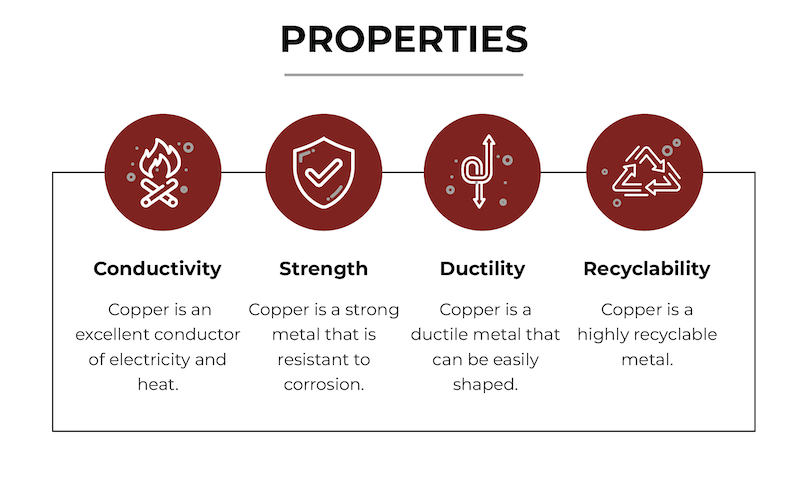

Like any other natural resource, the availability of pure or native copper from the ground is in limited supply. The good news is that copper can easily be recycled—in fact, almost a third of the copper purchased today is recycled. Copper is unique in its tolerance for continuous re-melting and reuse without losing properties.

The United States and Chile are currently the world's top copper producers today. Russia, Canada, and China are other countries where copper is mined.

Pure Copper Is Rare, But Copper Ores Are Abundant

As mentioned, pure copper is rare because most of it is naturally combined with other chemicals to form copper ores. The most common copper ores — there are about 15 of them mined in 40 countries— are sulfide ores.

Facts About Copper

1) Pure copper melts at 1,981 degrees Fahrenheit (1,083°Celcius). Superior heat transfer, electrical conductivity, and corrosion resistance are its three most important properties.

2) Twenty-nine mines account for 99% of copper production in the U.S.

3) Copper is a mineral that plays an important role our everyday lives. It is highly ductile, malleable, electrically conductive and extremely resistant to corrosion. These properties make it an important industrial metal. It’s also a key dietary nutrient, and has antimicrobial properties that are becoming more valued every day for the ability to prevent infection.

4) Copper is the 29th element on the Periodic Table. A semi-precious, nonferrous metal, it has hundreds of uses, including electrical and electronics, plumbing, construction, architecture, general industry, transportation and health care.

5) Copper ranks third in the U.S., behind only iron and aluminum, in quantity consumed.

6) There are an estimated 1.6 billion metric tons of copper in the U.S, mostly in Arizona, Utah, New Mexico, Nevada, and Montana.

7) Brass and bronze are the most well-known families of copper-based alloys. Brasses consist of copper and zinc, while bronzes are mostly copper alloyed with tin, aluminum, silicon or beryllium.

8) C36000, a leaded yellow brass, is extremely easy to machine and has become the benchmark for metals machinability.

9) Brass is the standard alloy for the manufacture of precision products such as clocks, watches, and navigational instruments because it’s easy to manufacture and machine, and it is highly corrosion resistant.

10) Bronze is harder than pure copper, which is why the Egyptians used it for their weapons and tools. It is also famous as the base metal for Egyptian sculptures. Bronze expands when heated—filling nooks and crannies of the mold)—then contracts when it cools, allowing the sculpture to be easily removed from the mold.

11) Other copper alloy families include copper-nickel, copper-nickel-zinc, which are often referred to as nickel

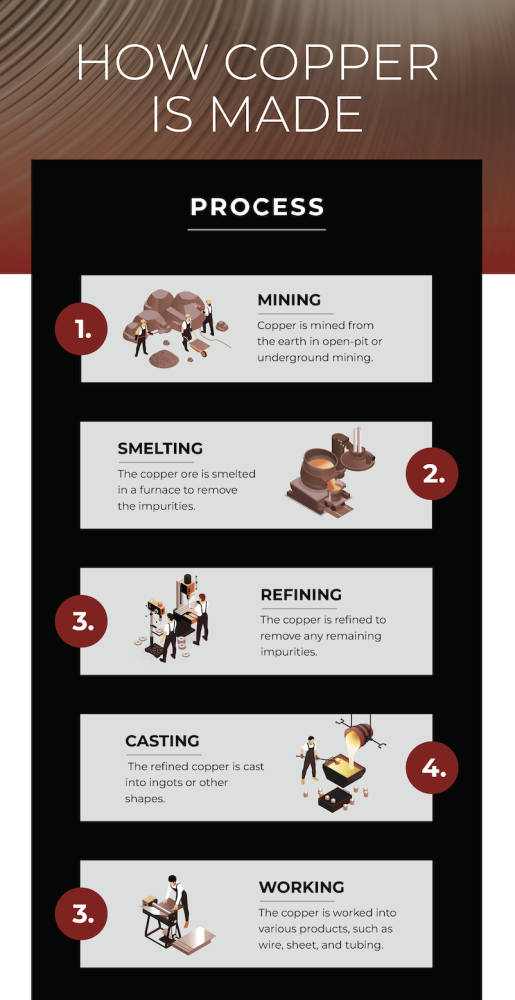

How Is Copper Made?

The copper creation process varies based on the type of constituent ore and purity the final product needs to be. Each method comprises a number of steps to remove, physically or chemically, the unwanted materials, therefore increasing the concentration of copper. These steps can occur at the mine or at separate facilities.

Where is copper mined? How is copper is processed? Let’s take a look at how copper is formed.

Mining Copper

Sulfide ores typically are extracted from large open-pit mines via drilling, and then blasted with explosives. With this method, the overburden, which is the material that lies immediately above the ore, is removed to uncover the ore deposit. The result is an open pit that could be more than a mile wide. This method requires a road to provide access for the equipment. The uncovered ore, once gathered by power shovels and deposited into large dump trucks, is ready for transport out of the pit.

Copper Concentrating

Once the copper ore is transported from the open pit, it must be cleansed of waste materials, such as dirt, clay and numerous minerals that bear no copper. This is called concentrating, and it’s usually accomplished through a method which entails crushing and grinding the ore in order to separate it from the waste materials (rock and other particles). Here are the steps in the concentrating process.

After crushing, workers mix the ore with water and grind it into even finer particles using a rod mill. The mill is comprised of a cylindrical container filled with many short lengths of steel rod. When the cylinder rotates on its horizontal axis, the rods spin and crush the ore into tiny fragments of about 0.13 inches (3 millimeters) in diameter. The combination of ore and water is broken down even further in two ball mills, which use steels balls to grind the ore instead of rods.

The slurry of ore that emerges contains finely ground ore particles of about 0.01 inches (0.25 millimeters) in diameter.

Now various chemical reagents are mixed with the slurry, coating the copper particles, and a frother (pine oil or long-chain alcohol) is added to help separate the copper from other undesirable materials. The mixture, injected into flotation cells, is aerated through the bottom of the tanks. The chemical reagents cause the copper particles to cling to the bubbles as they rise to the surface of the slurry.

Finally, a frother transforms the mixture into a thick layer of bubbles, which overflows from the ball mill tanks into collection troughs. The bubbles condense and the water drained off, leaving a mixture called copper concentrate. The mixture contains 25-35% copper, in addition to copper and iron sulfides and small bits of gold, silver and other matter. The leftover waste—known as tailings or gangue—is pumped into settling ponds to dry.

The Copper Smelting Process

After the waste is separated, the iron and sulfur must be removed from the copper concentrate. Called smelting, the process usually involves one or two furnaces.

The process starts by feeding the copper concentrate into a furnace along with a silica material called flux. Oxygen-enriched air forced into the bottom of the furnace, combusts with fuel oil to melt the copper and flux. This molten mixture then collects at the bottom of the furnace. Most of the iron in the concentrate combines with the flux to form a slag, which floats on the surface of the molten metal much like scum on the surface of broth. It is skimmed from the surface of the molten material in the same manner. The sulfur in the concentrate combines with the oxygen to sulfur dioxide, which is exhausted as a gas and is used to produce sulfuric acid. The molten material that remains at the bottom of the furnace, called the matte, is a mixture of copper and iron sulfides that contains about 60% copper by weight.

The matte is transferred to a second furnace called a converter. Additional silica flux is included in the mix, and oxygen injected through the furnace, causing the flux to react with the remaining iron to form a slag. At the same time, oxygen reacts with the remaining sulfur and forms sulfur dioxide. The slag is fed back into the furnace to serve as a flux, while the sulfur dioxide goes to an acid plant for processing. Then, injected oxygen removes most of the sulfur. The resulting material, blister, is comprised of about 99% copper by weight.

The Copper Refining Process

The copper blister is 99 percent pure copper, but it still contains enough sulfur, oxygen, and other impure materials to hinder further refining. To remove or reduce the levels of impurities the blister copper is fire refined before being sent for final electro-refining.

Heated in a furnace similar to a converter, the blister copper has air circulated through it to oxidize some of the impurities. In some cases, a sodium carbonate flux is to remove arsenic and antimony traces. After a sample of the molten material is inspected and the impurity levels are determined to be acceptable, the molten copper—about 99.5 percent pure—is poured into molds, forming electrical anodes which work as positive terminals in the electro-refining process.

The slime that collects at the bottom of the tanks contains gold, silver, selenium and tellurium. It’s collected and recycled to recover these precious metals.

Casting Copper Cathodes

After the refining phase, the copper cathodes are cast into various shapes such as ingots or rods, depending on the final application. Ingots are bricks, which are remelted to make brass and bronze products. Rods are round and are usually cast into very long coiled lengths. The copper is then made into wire.

Getting Copper To Market

Now that we’ve looked at how copper is made, lets discuss how it gets to market. Copper sold by mining companies comes in two forms—concentrate or cathode. Concentrate is a powder often sold to smelters that contains 24 to 40 percent copper. Although selling terms vary, in general the smelter pays about 96 percent of the value of the copper in the concentrate, less any treatment and refining charges.

Treatment charges are calculated on a per ton basis, while refining charges are calculated per pound of metal refined. Although the charges vary with the market, they’re usually fixed annually. Both of these charges fluctuate and tend to increase when the availability of copper is high.

Miners normally provide copper the concentration levels, although spot checks by third parties while the material is in transit to the refiner are not uncommon. In addition, the mine may be assessed penalties if the copper concentrate is determined to contain unacceptable levels of deleterious elements, such as lead or tungsten. On the other hand, miners receive credits for valuable mineral content in the concentrate, such as gold and silver. Treatment and refining charges are levied on each of these metals.

Smelters generally charge tolls, but they also sell refined metals for miners, meaning that all the risk and reward associated with changing copper prices accrues to the miners.

Copper concentrate is typically sold as an intermediate product via spot or long-term contracts. Spot contracts pay miners according to the price of copper when the smelter makes the sale. Long-term contract pricing pays based on a price that has been agreed to for the future, usually 90 days from time the mine delivers concentrate to the smelter.

Copper In The Home

Now that we've explored the history of copper, and how copper is made, let us focus on how we use it in the home. Copper has been a popular material used in building and home decorating for several thousand years. It’s not only a great conductor of heat and electricity, as already discussed, but it’s malleability and attractive reddish-orange hue makes it a wonderful touch for home décor, regardless of almost and theme or trend.

Copper is compatible with a range of styles, from early American to 17th century French, and modern to traditional. Here are some way copper can be incorporated into a home’s décor.

Hanging Pots

Copper has the ability to make something that’s purely functional decorative. Take copper pots and pans for example. Any kitchen will take on a more rustic, well-used feeling with the use of copper pot and pan hanger. You can keep these items looking shiny and new rubbing them down with copper polish once in a while.

Wall Décor

While too many copper items can make your home look and feel like a metalworking shop, a little bit here and there will provide a fresh feel. Copper wall décor is a great way to do this. Things like plaques, pressed tiles, or copper-rimmed mirrors can do amazing things to a room.

Cabinet Hardware

Whether it’s drawer pulls or door knobs, cabinetry hardware makes a beautifully strong statement. In the kitchen, bathroom or anywhere else, copper hardware imparts a classic, timeless feel.

Countertops

Copper stops the growth of bacteria, which makes it an excellent choice for kitchen and bathroom countertops. Copper countertops also add vivid complements to your home and can become the most talked-about element in the house.

These are just a handful of ways copper can bring warmth and elegance to any home. Explore worldcoppersmith.com for additional ideas for your home.

Putting copper in your kitchen

If there are copper furnishings you’ve got in mind for your kitchen, but aren’t sure how you’re going to fit them in, you can consider making use of the 3-D Configurator to help you do so. You shouldn’t have to plan everything in your head, or have to spend the time having everything drawn up - there are simpler ways to do it. Using the 3-D configurator can save you time and headaches in planning out simple installations. For example, having a copper countertop installed may sound like a great plan, but where would it fit in your kitchen? You can have it all virtually laid out for you .

Copper makes for a great kitchen metal, for multiple reasons. Not only is it a unique tone that you don’t often see in kitchen hardware, but its antibacterial properties make it much more sanitary than other metal options - making it perfect for kitchen sinks, countertops, hardware, and more. It looks great, it’s unique, and it’s perfect for creating a more rustic feel in your home. Not only that, but it can look great when matched with other colors, too.

Often, you would look at copper as something that’s only used in things like cables - which is due to its high conductivity, but it can be so much more than that. It doesn’t have to be used for its conductive properties, but for its aesthetic properties, instead.

Why else is copper a great option?

While it’s not important to everyone, it’s important to note that copper is often a much higher quality than other metals on the market. Copper has to match a very high purity level that’s not held to other metals during the refining process, so you can be sure that your copper products are a higher quality metal overall. You know what you’re getting when you purchase a copper product, be it hardware of furniture.

Something great about copper that other metals don’t have to offer is that it’s very easy to recycle. While some old pots and pans might need to be thrown out, it can be difficult to recycle them into something new. It might take some time before they’re remade, or the metal is reused for something else - but that’s just not the case for copper. While it is in limited supply, it can be easily recycled when you’re done with it. You don’t have to feel guilty when it’s time to rid yourself of your copper hardware - as nothing lasts forever, because it’s going to be recycled into something else that’s perfectly functional. You might even find that the copper product you’ve purchased is already made of completely recycled materials, so don’t be afraid to invest in copper products if you’re environmentally conscious.

As a result of using copper in more places in your kitchen, your home is more sanitary. The antibacterial and antimicrobial properties help in more ways you can imagine, and what place is more important than in the kitchen? The hardware that you cook with, the sink that you wash your dishes with, and the counter than you prepare your food on top of. Cleaning products aren’t always 100% effective, so it doesn’t hurt to take extra measures against bacteria in the kitchen. Copper installations can help with that, saving you the hassle of worrying that there’s too much bacteria growing in your kitchen, without being able to do anything about it.

Get it while you can

Copper hasn’t been seen as a rare metal historically, as it’s pretty cheap and fairly easy to come by. However, due to its versatility and low expense, it has had very high demand - which has driven its rarity up over the years. Copper is becoming more and more scarce as time goes on, and the longer you wait to invest in your copper hardware, the more it’s going to cost you. If you’re going to match demand, it’s important that you invest now before it’s too late. While copper is still relatively cheap, you could be reaping the countless benefits that this metal has to offer your kitchen.

It might seem like jumping the gun, as copper in the kitchen isn’t the most popular choice, but times change - and it will become increasingly popular as copper becomes more and more of a precious metal.